Metrology

Beyond the fabrication of microstructures, sample analysis and measurement is of primary importance.

In Kirana laboratories different kinds of instruments are available for metrological analysis. Depending on the characteristics of the sample, the avaliable instruments are:

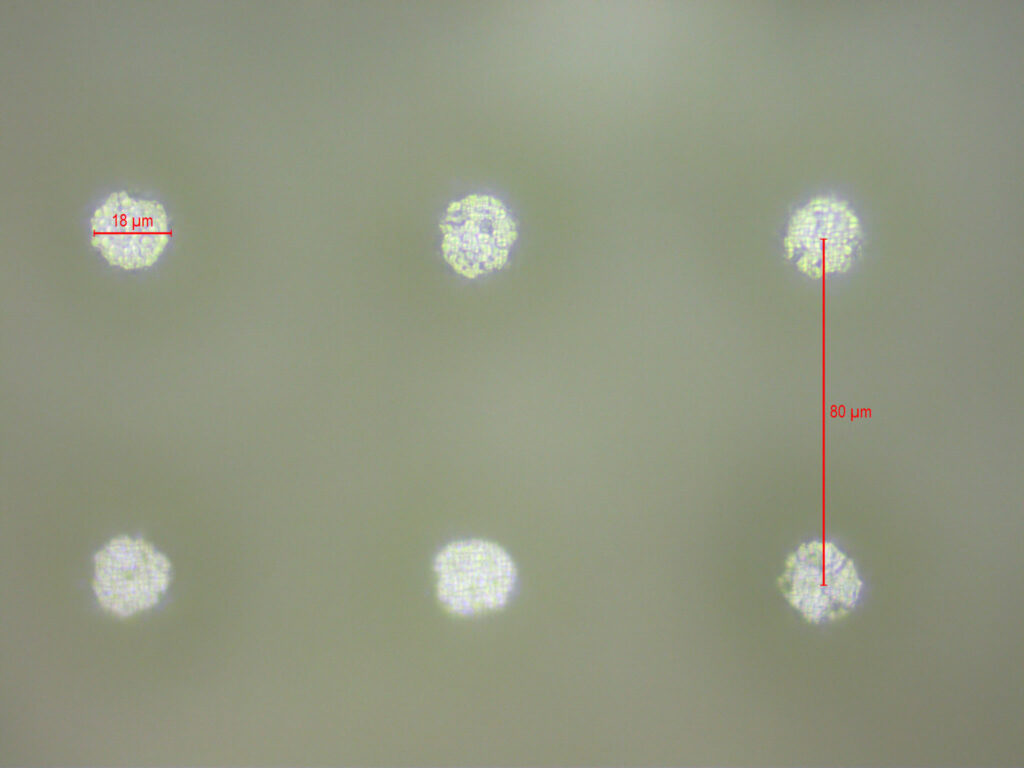

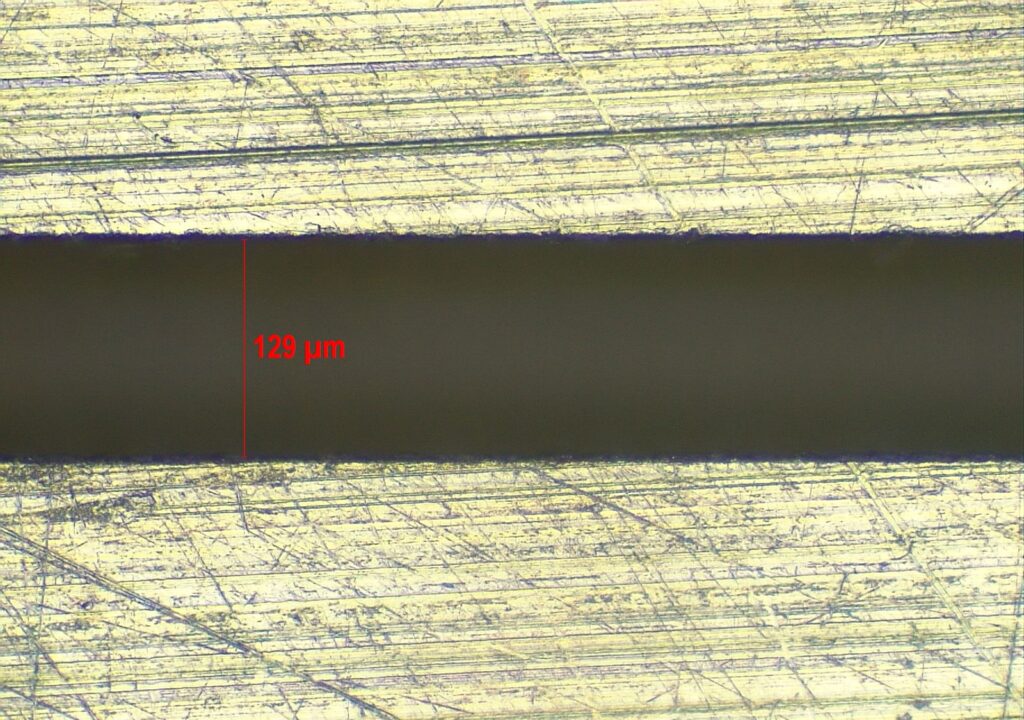

- Optical microscope with different magnifications. These insruments are periodically calibrated and enable certified measurements when specifically requested.

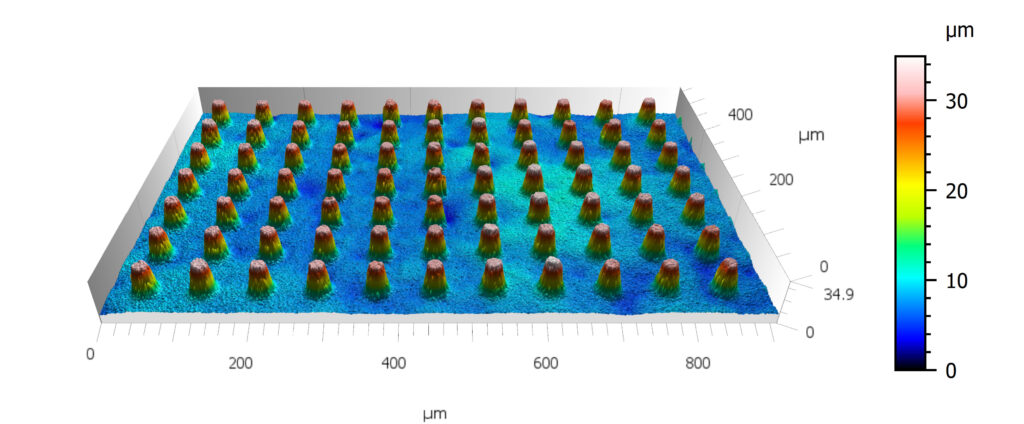

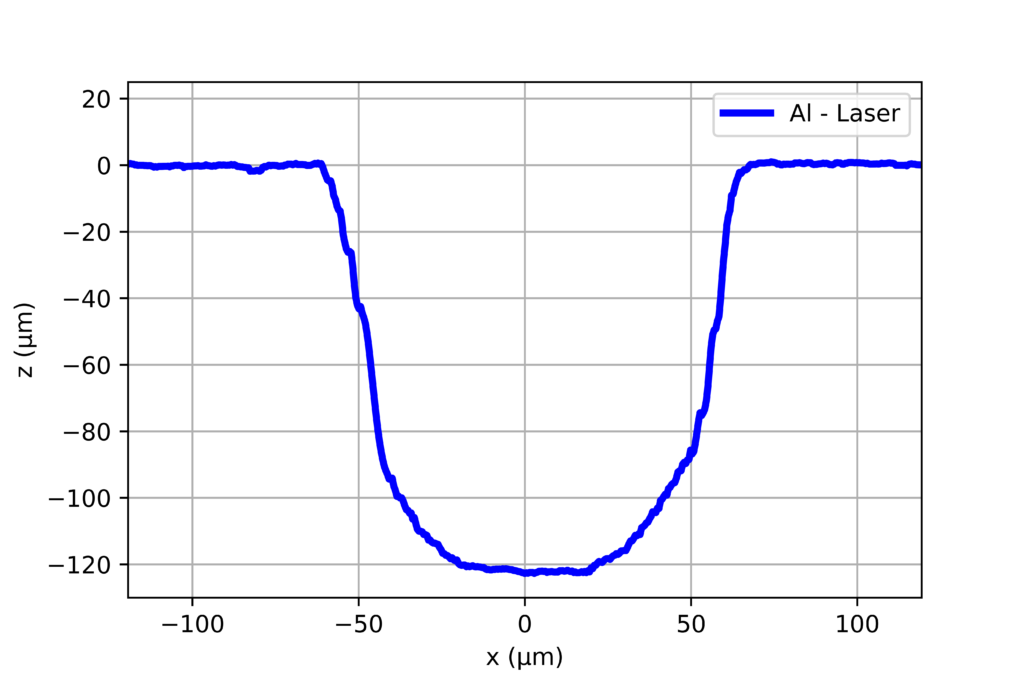

- Optical profilometer (White light interferometer). This instrument enables a high fidelity 3D reconstruction of sample surfaces.

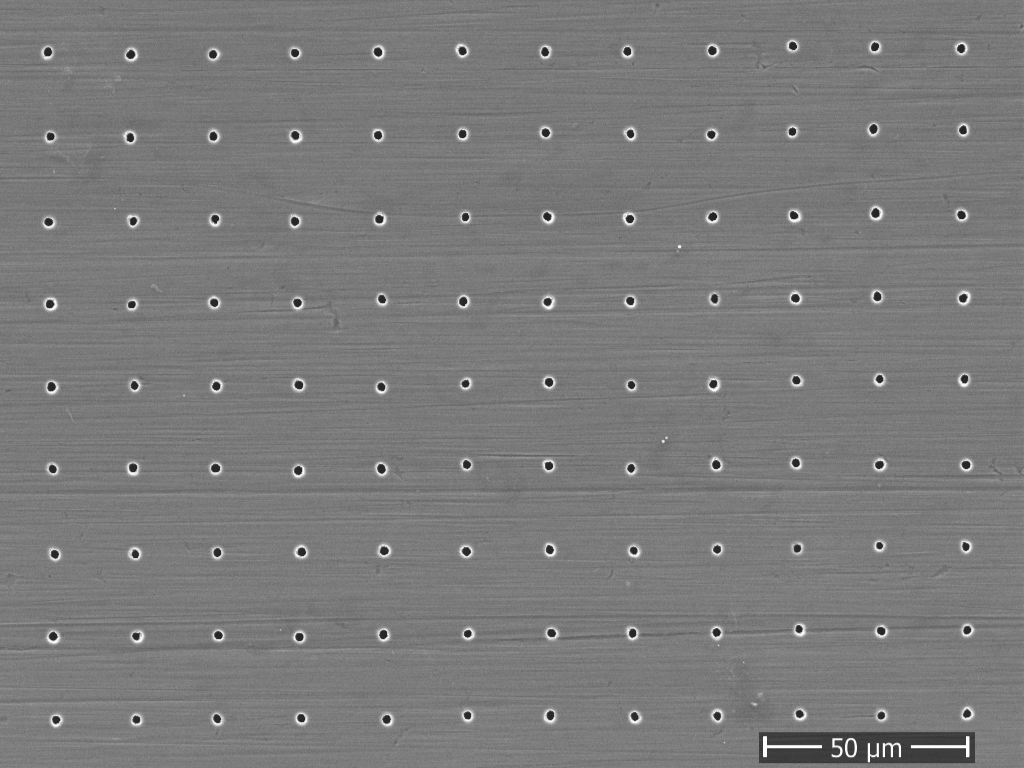

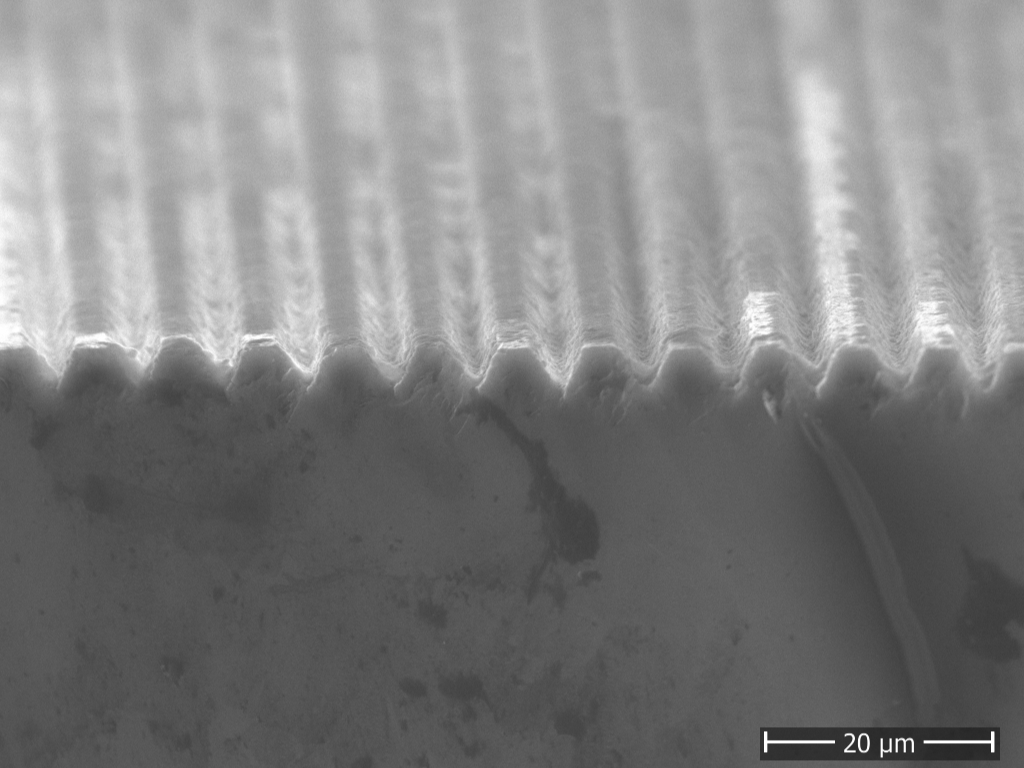

- Scanning Electron Microscope (SEM) equipped with secondary and backscatterd electrons detector for the observation of the smallest samples. Additionally, a sputter coater allows the observation of non-conductive samples

3D reconstructed pillars on ceramic material by optical profilometer

Micro-channel in aluminium with measurement of cross-section by profilometer

Scanning Electron Microscope images